Building Environmental Policy into the Bottom Line

Ready or not, environmental concerns are changing the marketplace. For a growing number of consumers, how something is made is becoming as important as the look and feel of the product itself. As consumers demand more transparency in organizations, and governments begin to enact more stringent environmental policies, even the most reluctant companies are thinking about upgrading their environmental policies. The question is where to start.

Three tile manufacturers address the growing green market

For a person, making a good living by doing worthwhile things can be a lifetime goal. For a company, as an aggregate of people, making change for the better can be more complicated. In some cases, country or state of origin may be critical. Taxation or fees may reflect the environmental footprint, and may include disposal levies, energy use disincentives and, now, a company’s CO2 footprint.

Where environmental legislation attempts to reflect real cost economics, it makes dollars and sense to save on resource use and limit toxic byproducts. But given the changes in consumer demand, even in places where environmental regulations are lax, it still makes sense for manufacturers to look for future-looking solutions.

Here, we look at the examples of three very different West Coast tile manufacturers, and how they have successfully incorporated environmental policy into their bottom line.

Bonfire Glass Tile is a small, two person operation out of Bend, Oregon. They make, in the words of co-owner Mare Schelz, “art deco designs with a handmade look.” For Bonfire, green tile production is achieved by keeping the scale small and controlling the inputs and outputs. Their production studio is situated next to the home of Jamie Branch and former glass blower Mare Schelz.

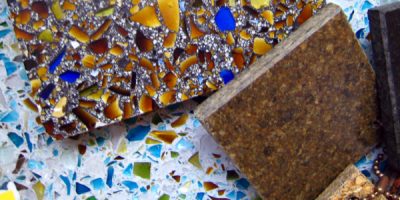

Bedrock Industries owns a glass recycling plant and factory store in Seattle WA. From the outset, Bedrock has been a manufacturer of 100% recycled glass products. Fifty percent of their output is glass tiles. Their 12 full time employees are also involved in the making and selling of garden art, landscape glass and indoor glass art.

Vancouver BC’s Interstyle Ceramic & Glass, sponsor of Aboutglasstile, is a company of 200 employees that makes both recycled and non-recycled tiles. Their environmental policies and practices have grown gradually, stemming from the company’s detailed approach to production and a concern for quality above all.

The products

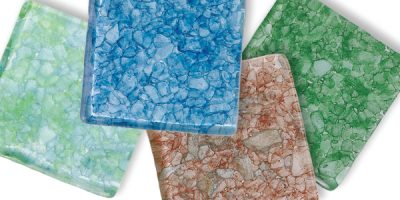

Bonfire makes all of its tiles out of post industrial glass, with a 90% recycled content. Interstyle has three lines that use 100% post industrial glass. They have also developed a counter top surface that is 100% post industrial recycled glass. Bedrock blends both post industrial and post consumer glass into its 100% recycled products.

Production Process

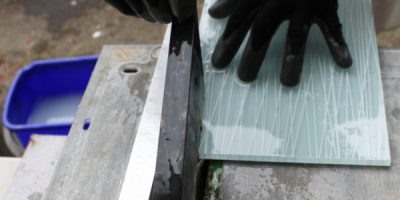

All three companies use fusing techniques, where kiln temperatures peak at about 800 degrees C. Though not low temperature in the conventional sense, this method, called “cool firing” consumes much less power than processes that transform glass powder or silica into tiles by sustaining kiln temperatures of 1400 C. On the tools side, Bonfire has also developed a process that also enables them to recycle their handmade tile molds.

Localization

None of the companies have their tiles made offshore, meaning a reduced shipping and transportation footprint. The raw materials for their recycled products are locally sourced as well. Bedrock and Bonfire hand-pick their post-consumer glass from the local waste stream; Interstyle uses local post-industrial glass waste.

Energy and Heat

Bonfire Glass Tile buys electricity through a renewable energy program offered by Blue Sky Energy, their utility company.

Bedrock estimates that their glass tiles use approximately the same energy as similar sized handmade ceramic tile, and about half of the energy used to make most cast glass products.

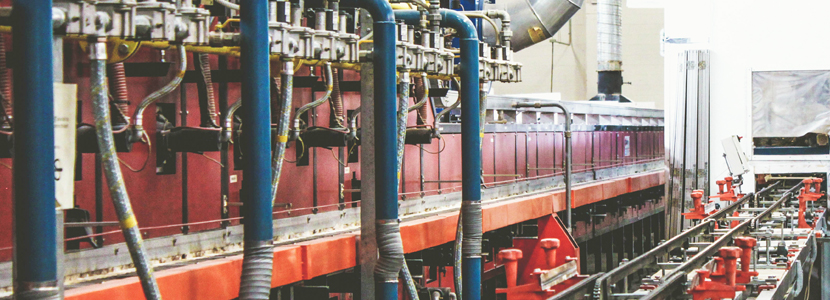

Interstyle’s computerized, modern continuous kilns, go 24 hrs a day, and run on natural gas. Development VP Kim Hauner claims the energy used is identical to what would otherwise be needed to heat their 75,000 sq foot factory in the winter – which, in fact, is exactly what the kilns are called on to do. The kilns are the only source of factory heat. Waste heat is sent via insulated pipe to their glaze drying rooms. By the time it is finished there, the temperature has cooled to 45 degrees C, and the heat is introduced into the open factory, recirculated by ceiling fans in the winter, and expelled through vented skylights in the summer.

Leading by inspiration

All three companies have experienced an upswing in interest in Green products in recent years. This is clearly evident at Bedrock’s factory store. A hub of inspiration and education on re-using resources in new ways, their store is a regular stop for locals and visitors, and has recently become a regular stop for tour buses. Bedrock also regularly holds community bottle drives, and make a point to pay higher than deposit ( and market) rates for the empty bottles that are dropped off at their factory.

Light

Interstyle uses skylights as well as low wattage lighting to reduce electrical needs. Their plant, which was built in 2002, used electronic ballasts, an improvement over the more toxic metal halide ballasts. They also used 32 Watt bulbs instead of the more popular 40 Watt bulbs. Today, there are newer lighting technologies available, but they the company is not about to revisit factory lighting just yet.

Bedrock’s 1950’s-built warehouse and factory has skylights and also a recent refit of modern, energy efficient T8 type florescent lights, replacing the outdated T12 fixtures. They have also recently installed florescent task lights in defined work stations.

Re-creating by recycling tiles

Interstyle provides re-glazing and decorative services to ceramic tile manufacturers or retailers. When tiles don’t sell due to unpopular styling or color, they can be shipped to Interstyle, who will apply new colors, patterns, texture or pictures to enhance their market appeal. Needless to say, this is far less intensive than disposing of unpopular products and starting from scratch. Bedrock also offers to make mosaic glass for artists’ use by re-firing their broken tile.

Packaging

All of Bonfire Glass tile’s packaging is made of recycled materials, and is supplied by local business. And, rather than printing a catalog, they send retailers to their website only. Bedrock uses recycled paper in its postcards and catalog materials, and ships in reclaimed cardboard. It also uses peanuts sourced by the Plastic Loose Fill Council for interior package fill.

In 2003 Interstyle bought a $10,000 cardboard fluffer by German company Intimus to convert waste paper and cardboard into packing materials. At first, they sent their own foraging crew out to pick up waste cardboard at various sources and deliver it back to the plant; today they have a company do this for them.

Water capture and recycling

Interstyle uses a closed loop water system to clean glazed tiles. Each time water is circulated, some is lost to the waste filter and to evaporation. The company has installed a water capture system on their 10,000 square foot roof, which collects more than enough water for their purposes.

Toxic chemicals

Volatile substances have been traditionally used for machinery cleaning. Many are carcinogenic and are dangerous in their manufacture, transportation, use and disposal. Interstyle has phased volatile cleaners out, replacing them with orange-based chemicals from the Florida Chemical Company. The company has also stopped using glycols as a medium of applying glaze to glass, now using non toxic pine oils.

At the end of the production cycle

There are always waste tiles produced in factories, either culled by quality control, or caused by production overruns. Bedrock sells seconds in its factory store, while Interstyle makes a point of finding a home for seconds, donating them to artists and organizations. Bonfire’s self-owned factory store enables them to move entire lines out their door, with virtually no wasted product.

Times change, but the adage, “if environmentalism is a fad, it will be the last one,” is probably more poignant than ever. There are better ways to solve old problems in manufacturing, and consumers are more than willing to seek them out.